Precision

How

meets

illumination

how to deliver

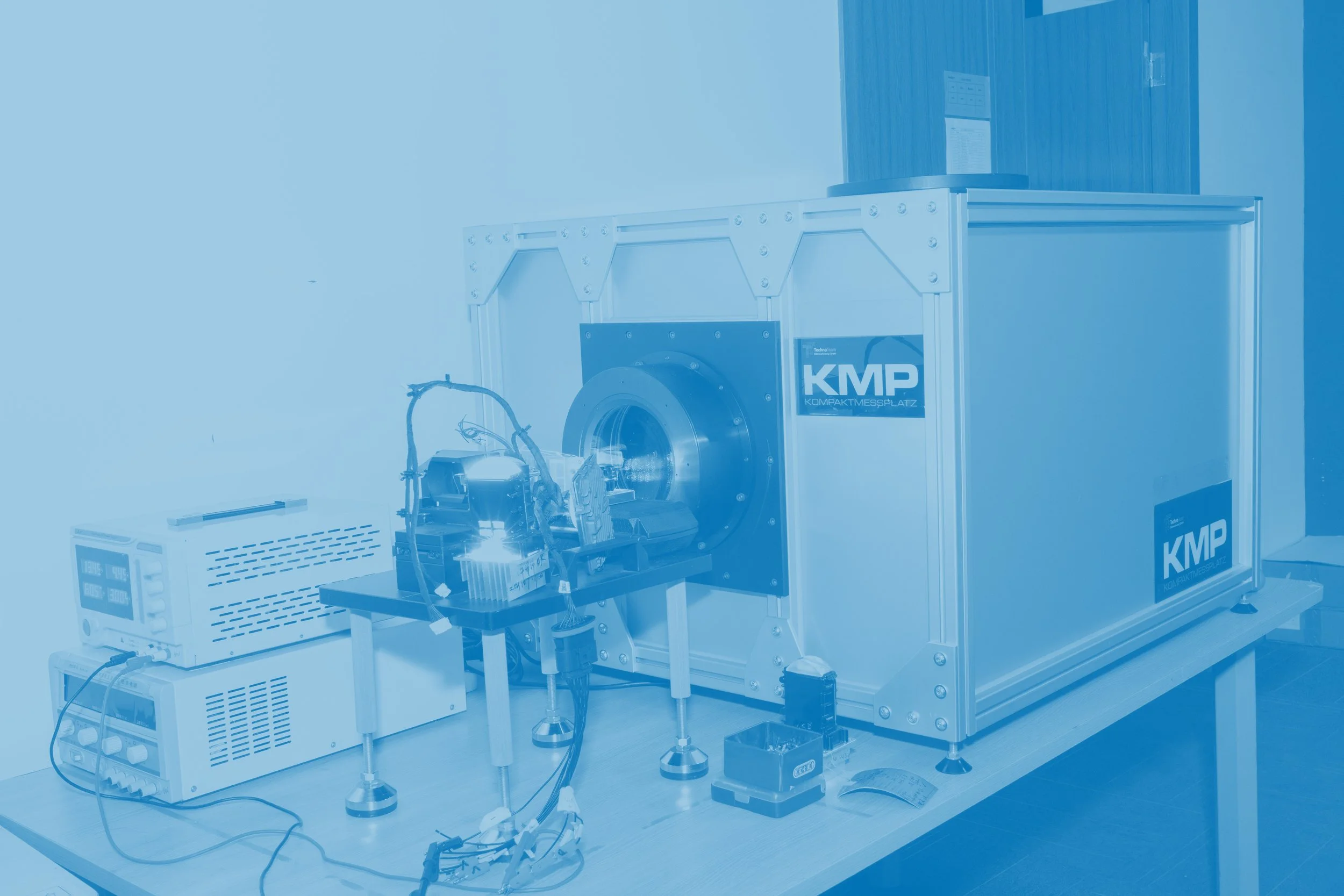

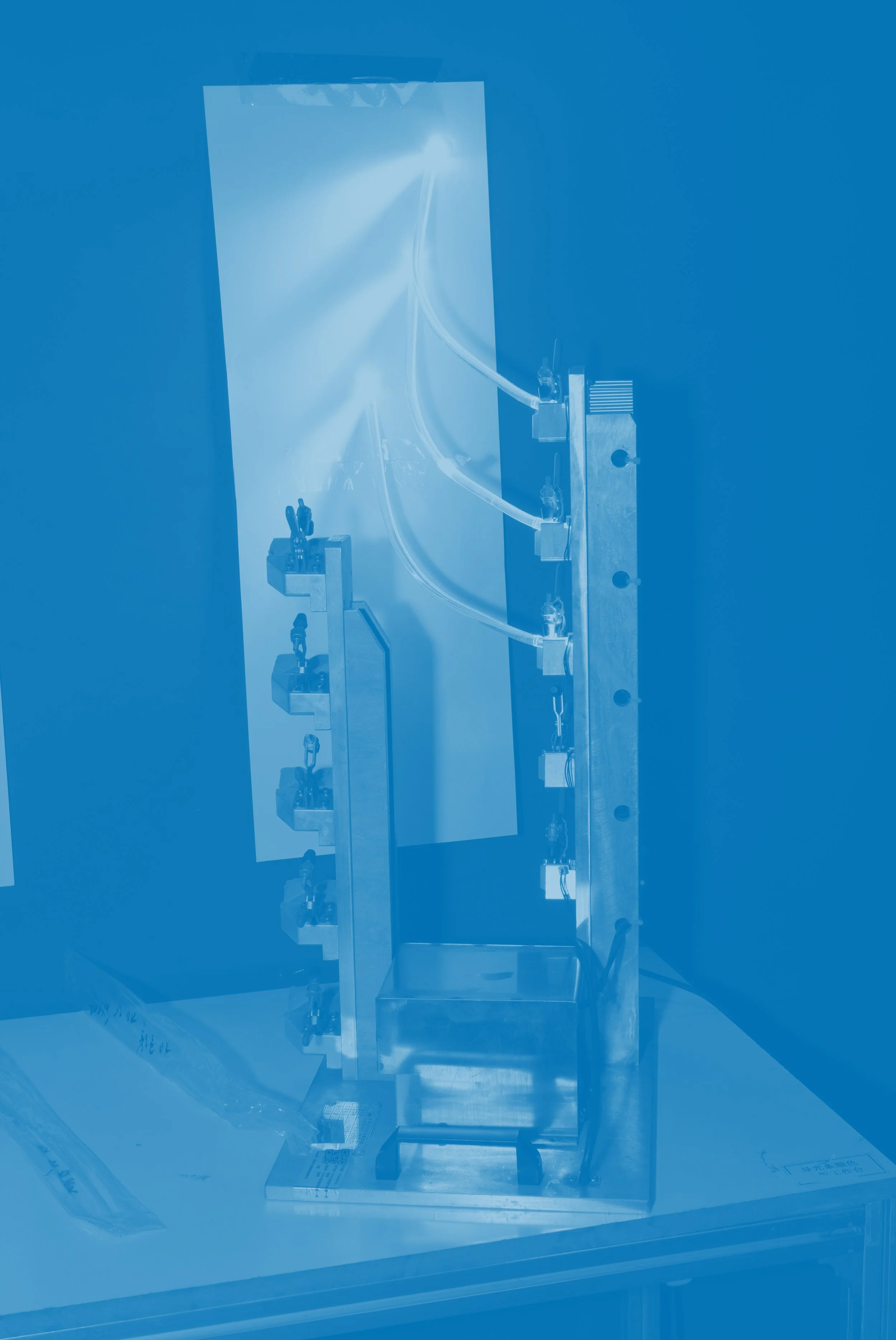

Leveraging years of dedicated experience in the automotive industry, our facility is equipped with a full suite of advanced in-house testing equipment. From material analysis and dimensional inspection to durability and performance validation, every stage of production is subject to rigorous quality control protocols. This comprehensive approach ensures that we consistently deliver products that meet—or exceed—industry standards for Precision, reliability, and long-term performance.

Pushing the Limits of Ultra-Precision Engineering

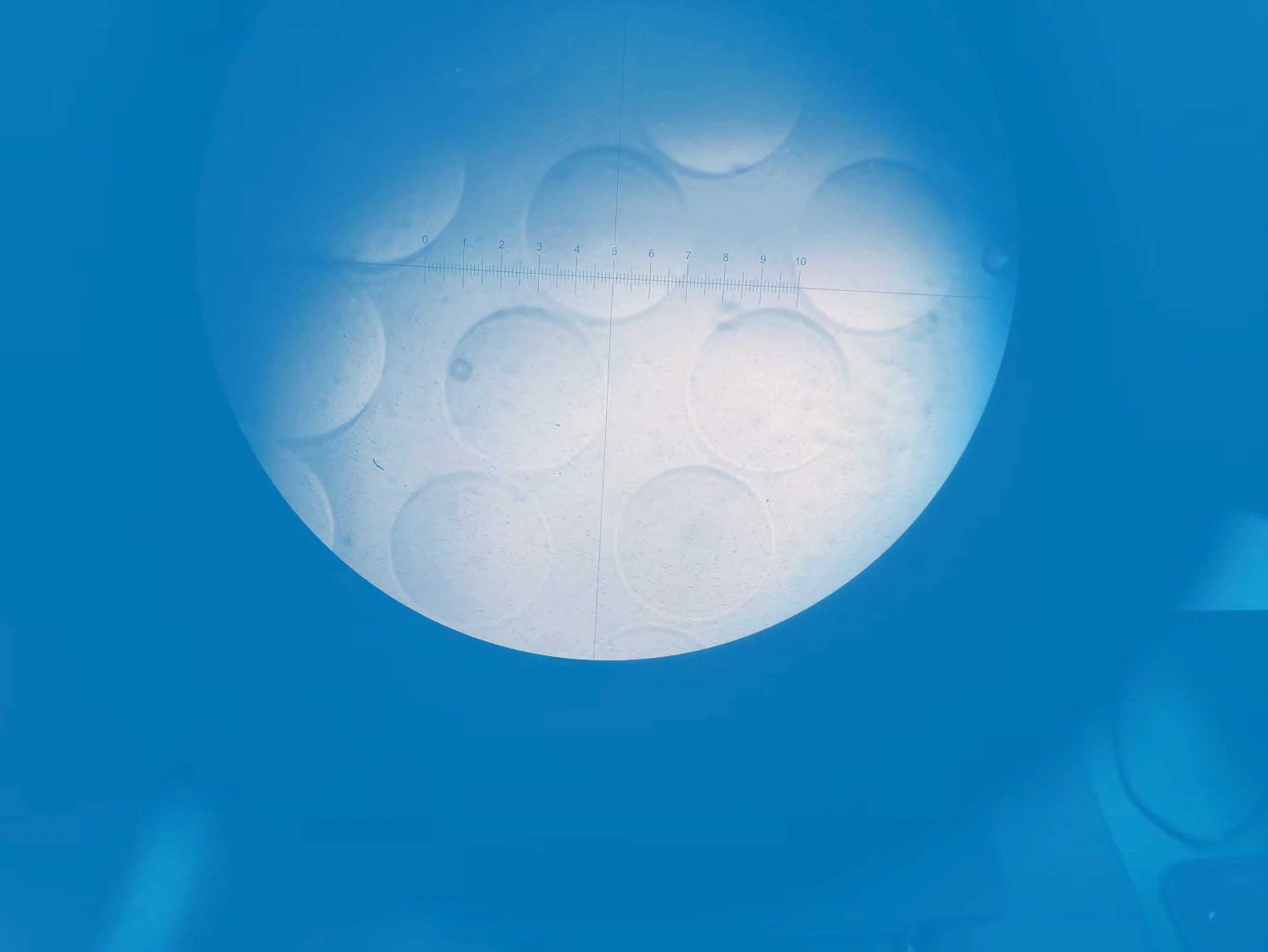

Our in-house tooling capabilities achieve nanometer-level precision—up to eight digits beyond the decimal point. This exceptional accuracy has been validated across demanding sectors such as aerospace, space technology, optical correction, and next-generation automotive manufacturing, demonstrating our advanced expertise in ultra-precision engineering.